Screw vacuum pumps

CONTACT

Lidická kolonie 47

586 01 Jihlava

Phone: +420 567 322 487

Service: +420 567 330 556

E-mail: info@vakuum-bohemia.cz

VAKUUM BOHEMIA offers sale, servicing, and repair of screw vacuum pumps by Busch, Rietschle and GEV.

Screw vacuum pumps are used in areas were other vacuum pumps cannot be used. Vacuum pumps are dry-running and are ideal for chemical and pharmaceutical applications. Vacuum pumps can pump explosive gases and be installed in areas where there is a risk of explosion (ATEX). Screw vacuum pumps are usually cooled by water. Their accessories include exchangers for air cooling or secondary water cooling. Parts in contact with the medium can have their surfaces modified in order to resist chemicals. Installation of rinsing allows the vacuum pump to be cleaned before stopping or during operation.

Operating principle of screw vacuum pumps

Screw vacuum pumps contain two screw rotors which rotate inside a cylinder. They are synchronised via a precision gear. Gas is captured in the space between the cylinder and the screw and then transported to the exhaust.

Standard vacuum pumps |

Sets |

ATEX certification |

|||

|

|

|

|||

| Screw vacuum pumps are oil-free vacuum pumps achieving a fine vacuum in a single stage. To pump corrosive gases, these vacuum pumps include a surface coating. |

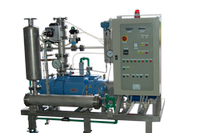

Screw vacuum pumps are often supplemented with customized instrumentation, auxiliary vacuum pumps, rinsing and control systems. |

Screw vacuum pumps and systems with these pumps are suitable for handling explosive gases or for use in environments with a risk of explosions. |

|||

Parameters of screw vacuum pumps:

|

Advantages of screw vacuum pumps:

|

Our services:

|

|

Applications:

|

Screw vacuum pumps are used in the following industries:

- chemical and pharmaceutical industries

- vacuum distillation and vacuum drying

- metal coating

- the environment

- research and development laboratories – other industrial applications

Table of models

| Model | Pumping speed [m3/h] | Max. vakuum [mbar] | Wattage [kW] | Connection | RPM | Weight [kg] | Size [(l x w x h) mm] |

|---|---|---|---|---|---|---|---|

| SC 0135 | 135 | 0,1 | 5,5 | DN 40 | diff. versions | 210 | 1385 x 495 x 476 |

| SC 0280 | 280 | 0,1 | 11 | DN 50 | diff. versions | 310 | 1653 x 570x 512 |

| SC 0390 | 390 | 0,03 | 15 | DN 65 | diff. versions | 400 | 1749 x 586 x 535 |

| SC 0720 | 720 | 0,03 | 22 | DN 100 | diff. versions | 600 | 1982 x 760 x 635 |