Elektror fans and blowers

We provide sale, service, repair and refurbishing of Elektror blowers and industrial fans. In the range of VAKUUM BOHEMIA, s.r.o., you will find Elektror air technologies for high pressure, medium pressure and low pressure ventilation technologies. We provide our services to companies from the Czech Republic and Slovakia.

We provide sale, service, repair and refurbishing of Elektror blowers and industrial fans. In the range of VAKUUM BOHEMIA, s.r.o., you will find Elektror air technologies for high pressure, medium pressure and low pressure ventilation technologies. We provide our services to companies from the Czech Republic and Slovakia.

Elektror fan technology by application:

- fans for explosive environments

- idle radial fans

- axial fans

- roof fans

- conveyor fans

Elektror industrial fans by power:

- low-pressure fans

- medium-pressure fans

- high-pressure fans

- large-volume fans

Elektror industrial fans

|

|

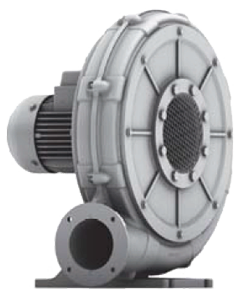

Fans for explosive environments Elektror ND ATEXThe stators of the ND ATEX series fans are made of an aluminum alloy and the rotor is made of galvanized steel sheet. Dynamically balanced impellers ensure low noise and high efficiency. They achieve a flow rate of up to 95 m³/min and a pressure differential of up to 2,200 Pa. The fans use three-phase or single-phase electric motors. Fans with ATEX motors can be placed in explosion hazardous areas. Key fan parameters:

|

|

|

Fans for explosive environments Elektror RD ATEXThe Elektror RD ATEX series medium=pressure fans are designed for transporting air and gases. They can achieve a pumping speed of up to 142 m³/min and a pressure differential of up to 10,600 Pa. The blower body is made of an aluminum alloy and the impellers are made of aluminum. This guarantees a long service life and corrosion resistance. Key fan parameters:

Applications and examples of the fan use:

|

|

|

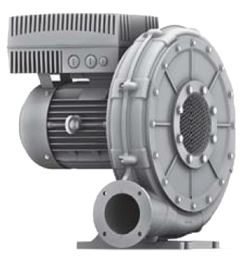

Elektror HRD FU/FUK fans for explosive environmentsThe Elektror HRD fans can be controlled via a remote frequency converter (FU) or a built-in frequency converter (FUK). The covers are made of an aluminum alloy and the impellers are made of aluminum. This guarantees a long service life and corrosion resistance. The fans can achieve a pumping speed of up to 100 m³/min and a maximum pressure differential of up to 17,300 Pa. The fans can reach speeds of up to 105 Hz (approx. 6,200 rpm). Key fan parameters:

|

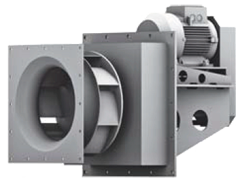

Idle radial fans Elektror PFL and PFMThe Elektror PFL radial fans can achieve pumping speeds of up to 300,000 m³/h (5,000 m³/min) and pressure differentials of up to 3,300 Pa. The Elektror PFM series can achieve pumping speeds of up to 300,000 m³/h (5,000 m³/min) and pressure differentials of up to 5,000 Pa. Both series can be supplied either with a direct belt drive operation or with a frequency converter. The fans in this product line have a standardized design, but are designed and delivered individually to suit the given project. Key benefits and functions include:

Applications and usage examples:

List of the idle radial fans can be found here ► |

|

|

Elektror MAF and HAFC axial fansThe Elektror MAF axial industrial fans can achieve pumping speeds of up to 200,000 m³/h (3,300 m³/min) and a maximum pressure differential of up to 2,000 Pa. The Elektror MAFC series, 145,000 m³/h (2,500 m³/min) and 5,200 Pa. Both series can be supplied either with a direct belt drive operation or with a frequency converter. The fans in this product line are standardized, but each delivery is modified to meet the specific requirements of a particular project. Key benefits and functions include:

Applications and usage examples:

|

|

|

Elektror RDF conveyor fansThe Elektror RDF conveyor fans have a capacity of up to 64 m³/min and a pressure of up to 7,150 Pa. The Elektror RDF fans are designed for direct transport of soft bulk materials. The fan body is made of an aluminum alloy and the impeller is made of steel. That ensures corrosion resistance. Key benefits and functions include:

Applications and usage examples:

|

|

|

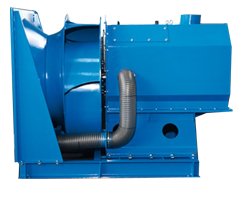

Elektror CFMT conveyor fansThe CFMT conveyor fans can achieve a pumping speed of up to 12,000 m³/h (200 m³/min) and maximum pressure differential of up to 4,250 Pa. The motor connection is direct, via clutch or belt, depending on the model. The housing and impellers are made of steel or stainless steel. A large number of accessories are available for the fans, such as compensators, vibration dampers, silencers, transition pieces, soundproof covers and protective grilles. The conveyor fans are available with an electric motor or with an internal combustion motor. The fans of the CFMT series are standardized but designed individually. Key benefits and functions include:

Applications and usage examples:

|

|

|

Elektror MAFR roof fansThe Elektror MAFR roof fans have a capacity of up to 67,000 m³/h (1,100 m³/min) and 1,100 Pa. They are supplied either with a direct belt drive operation or with a frequency converter. The fans are made of stainless steel. The impellers are made of plastic or aluminum. The fan blades create an air vacuum during movement, which comes out of the fan already under pressure. The MAFR fans are weatherproof. They are always sized individually pursuant to the given project. Available in a two-stage design or with a frequency converter. Key benefits and functions include:

Applications and usage examples:

|

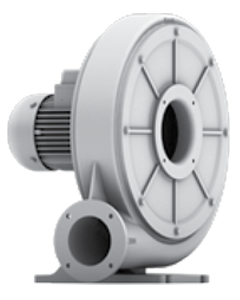

Elektror side channel blowers

|

|

Elektror SD side channel blowersThe side channel blowers of the Elektror SD series are equipped with sealed ball bearings with a service life of 22,000 motor hours. All engine parts are made of cast aluminum and are therefore highly resistant to corrosion. All blowers can be mounted in both horizontal and vertical positions. Key parameters of the ELEKTROR blowers:

Applications and usage examples of the Elektror side channel blowers:

|

|

|

Elektror 2SD side channel blowersThe fans have a capacity of up to 21.83 m³/min and 750 mbar. The cover and open impellers are made of an aluminum alloy. The fans have a built-in silencer, temperature sensor and direct drive. The fans are corrosion resistant. Key parameters of the ELEKTROR blowers:

Applications and usage examples of the 2SD side channel blowers:

|

|

|

Elektror SD-FU/FUK side channel blowersThe Elektror SD blowers have an external frequency converter (FU) or a built-in frequency converter (FUK). The fans have a capacity of up to 10.5 m³/min and 370 mbar. With higher speeds of up to 80 Hz (approx. 4,700 rpm). The stator is made of an aluminum alloy and the curved impellers are made of aluminum. This guarantees a long service life and corrosion resistance. Key parameters of the ELEKTROR blowers:

Applications and usage examples of the side channel blowers:

|

Service of industrial fans:

- Sale of industrial fans and vacuum technologies

- Warranty and post-warranty service of industrial fans

- Fan service at the customer's site

- Repairs and refurbishing of industrial fans

- Official Elektror service for the Czech Republic and Slovakia

VAKUUM BOHEMIA, s.r.o. services:

- Design and delivery of customized vacuum and pressure systems

- Training in the field of vacuum solutions

- Consulting in the field of vacuum technologies

- Rent of vacuum equipment

- Repairs and refurbishing of the Elektror fans